EV (Electric Vehicle) is Not future. Because EV is not EE

EE = (Neither Environment Friendly nor Economical)

Is EV an Unsuccessful Project?

Wait Wait Wait….

I understand I have claimed Big Word against Big World… Now its my responsibility to justify & prove my Point of view. I will do this by detailed analysis & facts….

Other issues with EV

Other Issues with EV: Infrastructure of Charging.

When in India still CNG not available throughout the country after so many years of CNG implemented. So what do you think about EV charging….

Other Many Issues, we will talk in detail, stay with us……

Lets Understand Now Brief of ….

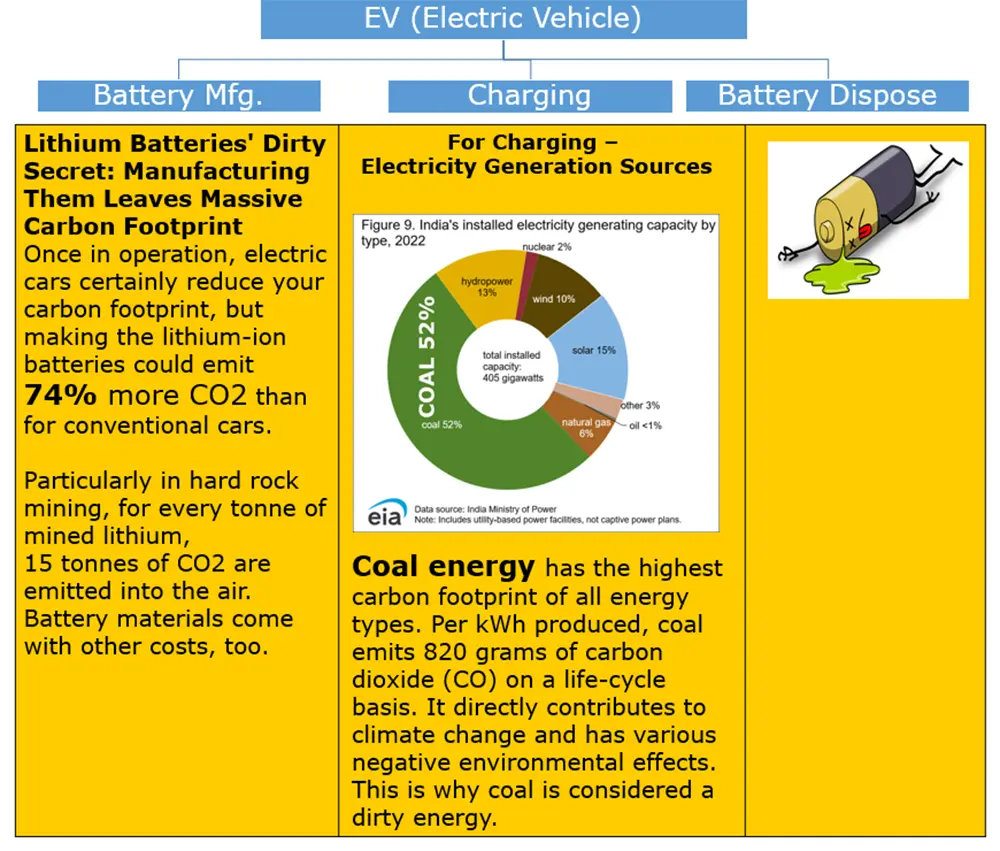

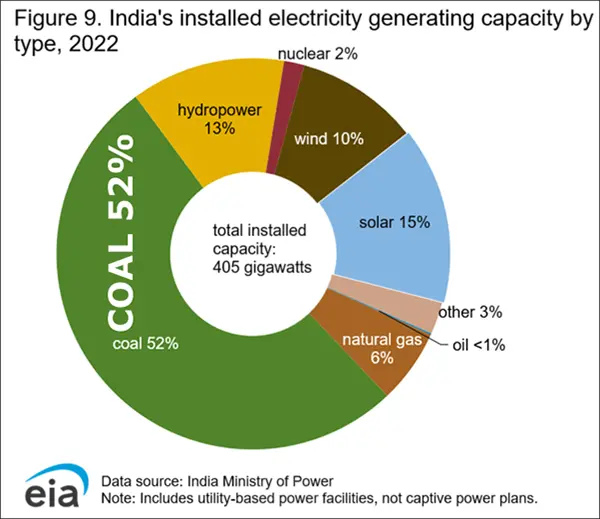

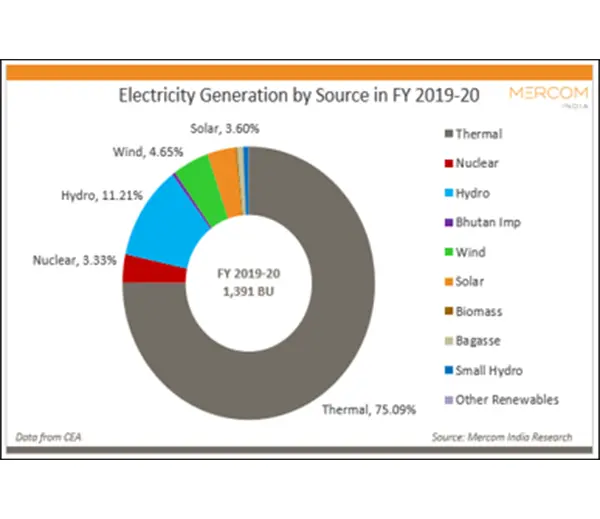

EV is not Environment Friendly….

COAL is Actually Black

- The sector's coal consumption increased from 300 million tonnes in 2006-07 to 600 million tonnes in 2017-18 (which is about two-thirds of the country's total coal consumption).

- Carbon dioxide (CO2) emissions from the sector have also risen, from 500 million tonnes in 2005 to 1,000 million tonnes in 2015.

- In 2016, India generated 3.1 giga tonnes (Gt) of CO2 equivalent (CO2 eq) emissions nearly 6.5 per cent of global GHG emissions.

- India's coal power generation's contribution was nearly 1.1 Gt CO2 eq; approximately 2.4 per cent of global emissions and one-third of India's total GHG emissions.

- Coal-based power contributes around 50 per cent of the country's fuel-related CO2 emissions.

Retirement

As per a CSE analysis in 2016, gross efficiency of around 60 per cent of the old capacity (34 GW) is lower than 33 per cent. Poor efficiency results in excessive coal consumption.

Replacement of this 34 GW capacity by supercritical capacity will reduce coal consumption by over 20 million tonnes per annum and CO2 emissions by 35Ð40 million tonnes.

In 2018, the NEP included a new target for the closure of 48.3 GW of end-of-life coal plants. Coal based capacity of 22,716 MW is under consideration for retirement during 2017Ð22. Additionally, a coal-based capacity of 25,572 MW has been considered for retirement by 2017Ð22, which will be completing 25 years of operation by March 2022.

India is missing out on the benefits of timely retirement of old capacity. Only 4.67 GW capacity has been retired between 2018Ð20 (March 2020)

Employees, land and coal linkages are the important assets for these power plants, better utilization of existing resources will be critical in prudently reducing CO2 emissions with minimum economic investment.

Coal Beneficiation

High ash content is among the reasons why Indian coal scores poorly on energy value. High ash content (of 30Ð50 per cent) creates many problems for coal users, including difficulty in pulverization, poor emissivity and flame temperature, low radiative transfer, and generation of excessive amounts of fly ash containing large quantities of un-burnt carbon.

This reduces the efficiency and increases the auxiliary power consumption of the plant. It is one of the reasons for higher CO2 emissions from Indian power plants.

What is the Carbon Footprint of Coal Energy

The carbon footprint is one of the ways we measure the effects of human-induced global climate change. It primarily focuses on the greenhouse gas (GHG) emissions associated with consumption, but also includes other emissions such as methane, nitrous oxide, and chlorofluorocarbons.

Carbon footprint: the amount of greenhouse gases and specifically carbon dioxide emitted by something (such as a person’s activities or a product’s manufacture and transport) during a given period

Basically, it is the amount of carbon emitted by an activity or an organization. This includes GHG emissions from fuel that we burn directly (e.g., heating a home, driving a car) and GHG emissions from manufacturing the products that we use (e.g., power plants, factories, and landfills).

What Is the Overall Carbon Footprint of Coal Energy

Coal is considered dirty energy because of its carbon footprint. On a life-cycle basis, coal emits 820 grams of carbon dioxide (CO) equivalent per kWh of electricity produced, which is the highest out of all of the fuel types.

To understand the carbon footprint of coal energy, we must assess its life-cycle and each stage’s carbon footprint. This life-cycle assessment (LCA) is a method to evaluate the environmental impacts of products and materials. Over the years, companies have strategically used LCA to research and create more sustainable products. So, let’s have a look at the LCA of coal energy!

Lithium Batteries’ Dirty Secret

Lithium batteries have revolutionized the way we store and use energy, powering everything from electric cars to smartphones. But behind the shiny exterior of these sleek, high-tech batteries lies a dirty secret – the manufacturing process used to create them leaves a massive carbon footprint.

According to a report from the International Energy Agency (IEA), the production of lithium-ion batteries generates between 150 and 200 kilograms of CO2 emissions per kilowatt-hour (kWh) of battery capacity. To put that into perspective, the average electric car battery has a capacity of around 60 kWh, meaning that its production generates around 9 to 12 tons of CO2 emissions.

One of the main culprits of these emissions is the energy used to power the manufacturing process. Most lithium batteries are produced in countries such as China, which rely heavily on coal for their energy needs. Coal energy has the highest carbon footprint of all energy types, releasing large amounts of greenhouse gases into the atmosphere during combustion.

Another factor is the extraction of raw materials such as lithium, cobalt, and nickel, which are essential components of lithium batteries. These materials are typically mined using heavy machinery, which requires a significant amount of energy and releases greenhouse gases into the atmosphere. In addition, the mining process can also cause environmental damage, including deforestation, soil erosion, and water pollution.

To address these issues, there has been a push towards developing more sustainable and environmentally friendly methods for producing lithium batteries. One solution is to shift to renewable energy sources such as solar and wind power to power the manufacturing process. In addition, researchers are exploring new ways to extract raw materials more sustainably, such as using bacteria or fungi to break down minerals.

Another solution is to improve battery recycling and reuse. By recovering materials from used batteries and using them to create new batteries, the environmental impact of battery production can be reduced. In addition, reusing batteries in applications such as stationary energy storage can further reduce their carbon footprint.

Overall, while lithium batteries have the potential to help us transition to a more sustainable future, it is important to recognize their environmental impact and work towards reducing it. By improving the sustainability of battery production and exploring new technologies and materials, we can create a future where we can harness the power of lithium batteries without harming the planet.